A 3D laser vibrometer captures vibrations in all three spatial directions at a single measurement point. To achieve this, three laser beams measure the same point from different angles. The measured vibration components – initially recorded in the respective beam directions as u, v, and w components – are then transformed into a Cartesian coordinate system (x, y, z).

There are two basic types of 3D laser vibrometers: The 3D single-point vibrometer measures the three-dimensional vibration at a fixed measurement point. The 3D scanning vibrometer additionally captures many points automatically in sequence and provides complete 3D mode shapes across an entire measurement surface.

SMART Scan+

SMART Scan+

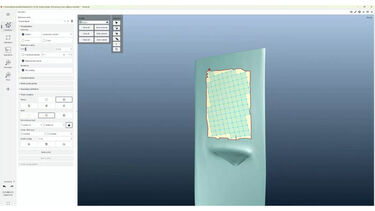

SMART 3D-Scan

SMART 3D-Scan

SMART Full Body

SMART Full Body

SMART Single+

SMART Single+

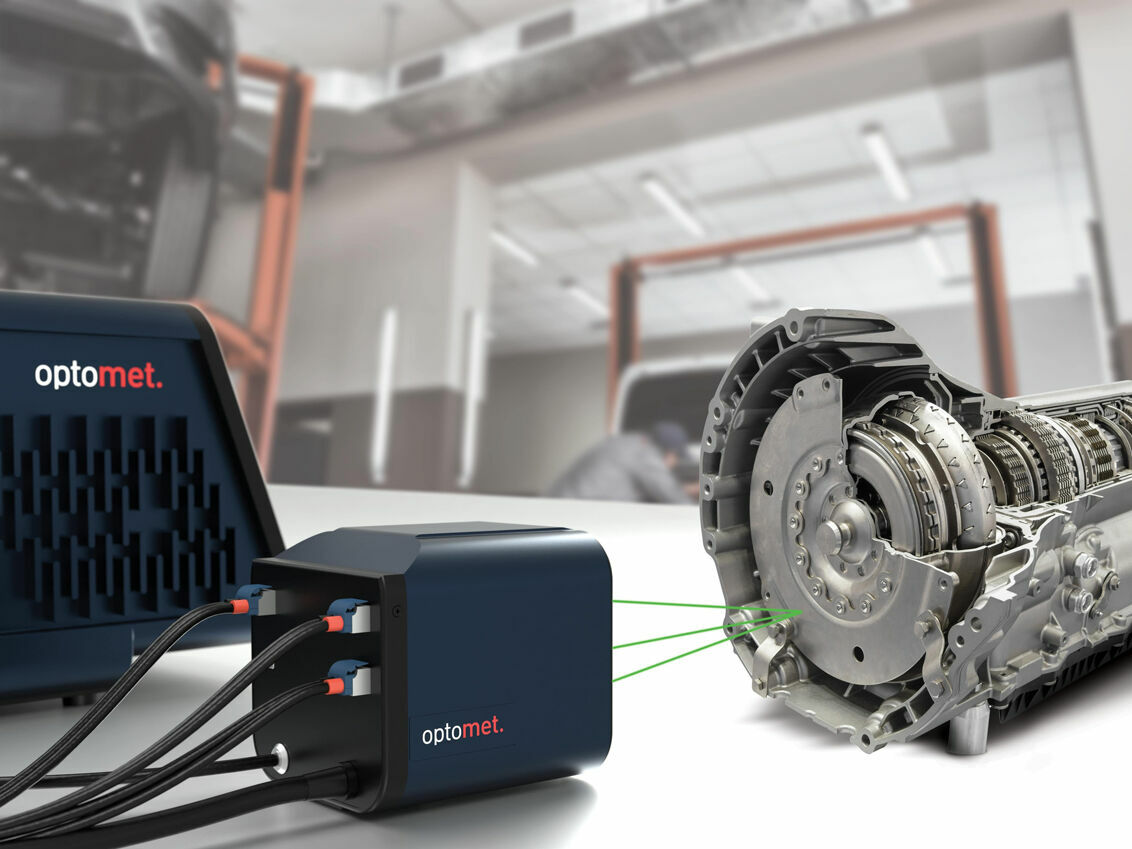

SMART Multi-Fiber

SMART Multi-Fiber

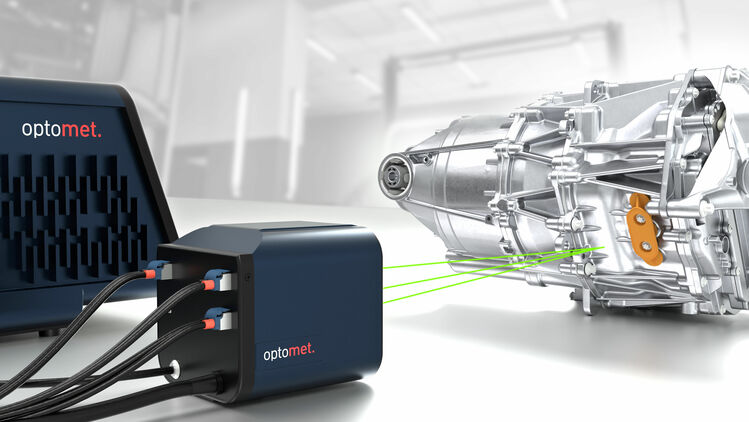

SMART 3D-Fiber

SMART 3D-Fiber

SMART DAQ

SMART DAQ

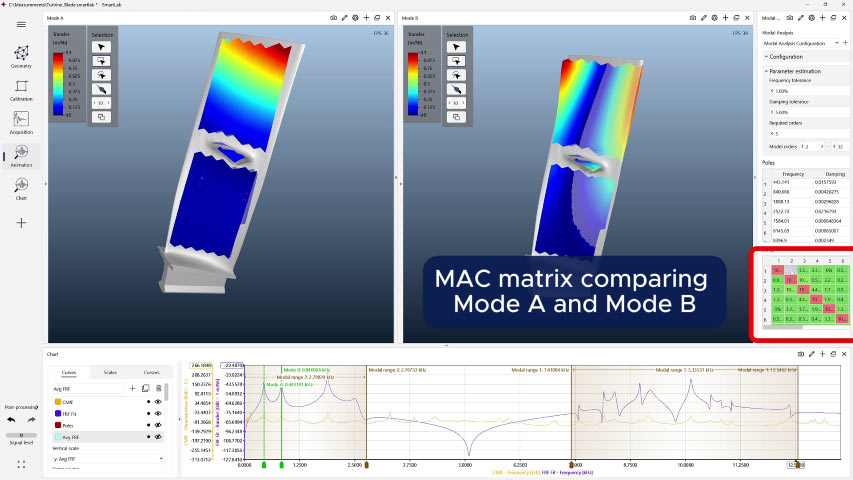

Software SMART Lab

Software SMART Lab

Scanning Vibrometer

Scanning Vibrometer

Vector-Series

Vector-Series

Vector-Micro-Optics

Vector-Micro-Optics

Nova-Series

Nova-Series

Nova-Xtra

Nova-Xtra

Fiber-Series

Fiber-Series

Fiber-Multiplex

Fiber-Multiplex

Fiber Micro Manipulator

Fiber Micro Manipulator

OptoSCAN

OptoSCAN

OptoGUI

OptoGUI

Single-Point Vibrometers

Single-Point Vibrometers

Scanning Vibrometers

Scanning Vibrometers

3D-Laser Vibrometers

3D-Laser Vibrometers

Acoustics & Ultrasonics

Acoustics & Ultrasonics

Aerospace and aviation

Aerospace and aviation

Automotive

Automotive

Biology & Medicine

Biology & Medicine

Brake noise

Brake noise

Civil Engineering

Civil Engineering

Electronics & Household Devices

Electronics & Household Devices

Materials Research

Materials Research

Medical technology

Medical technology

Tools & Machinery

Tools & Machinery

Turbine

Turbine

Wind tunnel testing

Wind tunnel testing