Acoustics and ultrasound measurements with innovative and precise measurement technology

Acoustics and ultrasound measurements with innovative and precise measurement technology

Laser Doppler vibrometers are indispensable tools for challenging work in the field of acoustics and ultrasonics. They visualize vibration directly at the source of sound generation: on a membrane or any other moving surface. Their non-contact measuring principle is precise, highly linear and free from environmental influences.

Optomet laser vibrometers have proven their value in the development of loudspeaker systems, in the construction of musical instruments, the development of ultrasonic sensors, microphones, mobile phones and ultrasonic sonotrodes but also in the acoustic design of consumer goods, white goods, automotive and aircraft components or in the validation of FE models.

Laser vibrometers from Optomet support manufacturers of musical instruments in the optimization of musical instruments with regard to sound quality, durability and design characteristics.

The examination of instrument strings is practically impossible with conventional contact sensors, as these are difficult to attach to the strings. Additionally, mass loading by sensors such as accelerometers would corrupt the dynamic response of the measurement object. A similar problem arises with the sound boxes of guitars and string instruments as well as the sound boards of pianos and grand pianos.

Optomet laser Doppler vibrometers allow to systematically investigate vibration amplitudes, resonance frequencies, damping and the effects of the choice of materials in the development of musical instruments, without the need of physically contacting and therefore influencing the characteristics of the instrument.

The vibration analysis of resonance bodies allows the detection and visualization of surface vibrations on the body of an instrument. Vibration modes or hidden sounds can be clearly identified and classified in the frequency spectrum. This enables a clear analysis of the unique sound of guitars, violins, pianos, drums and many other instruments.

An additional quality assessment and sound characterization is the time representation of the vibration propagation. This method clearly determines the time course of the wave propagation over the resonance body.

The propagation of sound waves in a medium (e.g. air) causes a spatial and temporal fluctuation in density. Since the refractive index and thus the speed of light change with the density of the medium, the changes in density caused by the sound waves can be made visible with the laser Doppler vibrometer.

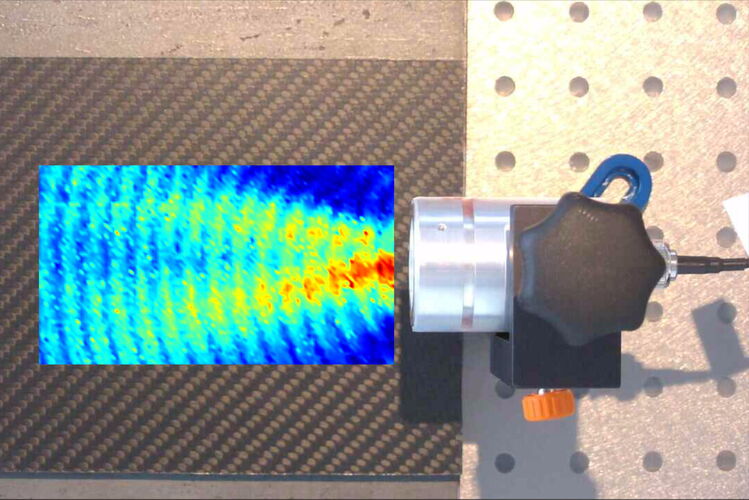

To do this, the laser beam that passes through the sound field to be measured is scanned on a static white surface and the reflected signal is detected. In contrast to the typical vibrometry applications, the interferometrically measured phase differences do not result from the movement of the reflecting surface, but from the variation of the transit time from the vibrometer to the reflector and back to the measuring device, which are caused by the density fluctuations.

Due to the fluctuations in the refractive index, the transit time of the laser beam varies from the laser Doppler vibrometer (LDV) to a reflector that is located behind the sound field to be measured and back to the vibrometer. A white wall can serve as a reflector, for example. This change in transit time leads to a phase change detected by the vibrometer.

Density and thus also pressure fluctuations caused by the sound waves can be visualized in this way with the OptoSCAN software. Application examples are the measurement of the sound field for the development of ultrasonic transducers and loudspeakers. The three-dimensional geometry of the sound field can also be reconstructed using tomographic methods.

Finite element methods (FEM) play a central role in acoustics for the precise simulation of complex sound fields and vibration patterns. FEM can be used to analyze and optimize resonance frequencies and vibration modes in detail.

Laser Doppler vibrometers from Optomet perfectly complement this method by providing experimental data that can be used to validate the simulations. This combination makes it possible to efficiently develop acoustic components, such as loudspeakers or sonotrodes, and to optimize sound insulation in various applications.

Ultrasonic transducers are often used in non-destructive testing methods or ultrasonic signal transmitters. The picture shows the sound field of a divergent ultrasonic transducer which was measured with an Optomet laser scanning vibrometer.

Ultrasonic acoustic vibrations with frequencies of 20 kHz and above are used to join thermoplastics and thin metal parts. Vibration velocities of several m/s lead to the necessary energy input required for the melting process.

The measurement range of up to 25 m/s of Optomet’s single-point and scanning laser vibrometers offers detailed insight into the complex welding process. They allow users to estimate simulation parameters, validate finite-element models, and contribute to the fine-tuning of the design of sonotrode and anvil.

A digital signal output of 32 bit makes smallest vibrations visible, even when superimposed onto much larger amplitude oscillations.

The long lifespan of the SWIR laser source even in continuous operation makes Optomet’s vibrometers ideal for end-of-line testing and quality control, as well as for inspection of piezoceramics received from suppliers.

High signal levels of Optomet’s SWIR vibrometers eliminates the need for any reflectivity enhancing surace treatments.

Optomet scanning laser Doppler vibrometer allow to measure the entire surface of a sonotrode and display the deflection shapes. In particular, unwanted modes with high amplitude, which have a significant impact onto the welding result, may develop at the edge of the sonotrode.

The cause and the origin of such problems can be identified efficiently using vibrometry. The validation of finite-element models allows a systematic improvement of the ultrasonic process and the equipment on a sound basis.