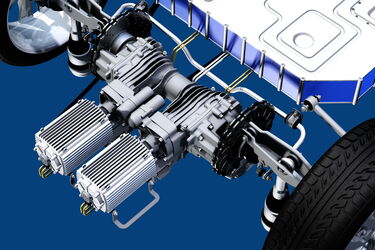

The duration of product development processes from concept to series production is getting shorter and shorter. This is particularly the case in the automotive industry, where the switch to electromobility is accelerating change. New components and the use of lightweight construction require extensive vibration analysis.

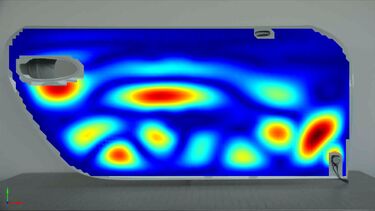

Even though the mechanical properties of components and entire component groups are increasingly and more precisely examined by numerical simulations, experimental measurements of physical objects are still required to validate these calculations. Non-contact measurement techniques such as laser vibrometry have the advantage that they do not influence the vibrations of the components and deliver excellent results in a very short time with little effort.

The superior signal quality of the Optomet infrared technology produces the best possible measurement results even on poorly reflective surfaces. This makes the devices suitable for measuring any component, regardless of its material or optical reflectivity. The Optomet’s ease of use and powerful measurement capability reduces development time.

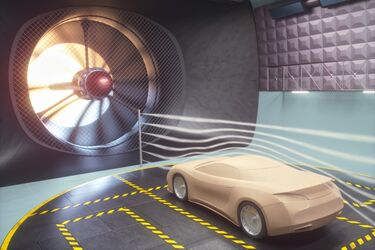

Whatever your non-contact vibration application, be it in the wind tunnel, on the rotation test rig, in the acoustics laboratory, for experimental modal testingor for the development of components such as sensors or drives, the Optomet team will be happy to assist you in selecting the suitable vibrometry solution and implementing it.

SMART Scan+

SMART Scan+

SMART 3D-Scan

SMART 3D-Scan

SMART Full Body

SMART Full Body

SMART Single+

SMART Single+

SMART Multi-Fiber

SMART Multi-Fiber

SMART 3D-Fiber

SMART 3D-Fiber

SMART DAQ

SMART DAQ

Software SMART Lab

Software SMART Lab

Scanning Vibrometer

Scanning Vibrometer

Vector-Series

Vector-Series

Vector-Micro-Optics

Vector-Micro-Optics

Nova-Series

Nova-Series

Nova-Xtra

Nova-Xtra

Fiber-Series

Fiber-Series

Fiber-Multiplex

Fiber-Multiplex

Fiber Micro Manipulator

Fiber Micro Manipulator

OptoSCAN

OptoSCAN

OptoGUI

OptoGUI

Acoustics & Ultrasonics

Acoustics & Ultrasonics

Aerospace and aviation

Aerospace and aviation

Automotive

Automotive

Biology & Medicine

Biology & Medicine

Brake noise

Brake noise

Civil Engineering

Civil Engineering

Electronics & Household Devices

Electronics & Household Devices

Materials Research

Materials Research

Medical technology

Medical technology

Tools & Machinery

Tools & Machinery

Turbine

Turbine

Wind tunnel testing

Wind tunnel testing