Conventional vibration sensors such as accelerometers must be mounted directly onto the test object – using adhesive, screws, or magnets. This mechanical coupling alters the vibration characteristics of the specimen, especially for lightweight, sensitive, or small structures.

When conventional contact sensors reach their limits

Mounting and cabling affect measurement quality

Mounting conventional sensors requires significant effort: cabling, adhesive layers, or positioning errors can further distort measurement results.

Typical disadvantages of conventional sensors:

- Mass influence: Added mass alters the natural frequencies of the structure.

- Complex installation: Gluing, aligning, curing, and routing cables.

- Scalability effort: More measurement points require significantly higher installation effort.

- Limited application range: Measurements on hot, moving, or hard-to-reach objects are hardly possible.

- Limited resolution: Often restricted to the micrometer range with a narrower frequency bandwidth.

Mechanical coupling can influence measurement results – particularly in sensitive or lightweight components.

Laser Vibrometers: Precise measurement without influencing the object

Laser-Doppler Vibrometers (LDV) measure non-contact – meaning: no mass, no cabling, and no interference with the vibration behavior.

The laser detects the surface vibration velocity via the Doppler effect and provides precise, reproducible results – even on sensitive, hot, or moving components.

Advantages of non-contact measurement:

- No physical contact – no influence on the test object.

- High resolution: Detection of displacements down to 50 femtometers (≈ 1/2,000 of an atom’s diameter).

- High spatial resolution: Precisely captures local vibrations, even on small structures.

- Wide frequency range: DC to 50 MHz (SMART Series) and up to 25 MHz (CLASSIC Series).

- Fast, reproducible results with minimal setup effort.

- Integrated data acquisition and visualization with SMART Lab.

Laser Doppler Vibrometry delivers precise measurement data – contactless and without affecting the test object.

Contact-based vs. Non-contact Vibration Measurement

|  | |

|---|---|---|

| Influence on the object | Additional mass changes natural frequencies and damping | No influence on the test object |

| Setup & handling | Requires gluing, screwing, or cabling | Fast, contactless setup without mounting sensors. Accelerometers (reference sensors) can be connected additionally |

| Measurement range | Up to a few tens of kHz (depending on the sensor) | DC to 50 MHz (SMART Series), up to 25 MHz (CLASSIC Series) |

| Resolution | Typically in the micrometer range | Down to 50 femtometers (≈ 1/2,000 of an atom’s diameter) |

| Signal processing | Requires external DAQ or analysis hardware | Integrated data acquisition, signal processing, and visualization (SMART Lab) |

The Optomet SMART series

Vibration measurement on a new level

The SMART Series from Optomet combines state-of-the-art Laser Doppler Vibrometry with comprehensive NVH measurement technology in one compact system.

The product family includes SMART Single+, SMART Scan+, SMART 3D-Scan, SMART Multi-Fiber, SMART 3D-Fiber, SMART Full-Body, and the SMART DAQ system – integrating all key components for vibration measurement, data analysis, and visualization within a single platform.

Modular, precise, intuitive

The modular concept enables customized configurations – from single-point measurements to complex 3D analyses. Intelligent functions simplify the measurement process, minimize potential errors, and ensure maximum accuracy.

Learn more about the SMART Series and its versatile applications here.

"For more than 20 years, we have been developing precise measurement technology for research, development, and industry – from individual measurement tasks to complex system solutions."

Tobias Schröder (M.Sc. Mechanical Engineering)

Head of Sales & Marketing

The Optomet CLASSIC series

Reliable vibration measurement with proven technology

Optomet laser vibrometers of the CLASSIC Series stand for precise, non-contact vibration measurement using mature and proven technology. They combine robust design, high measurement dynamics, and a wide frequency range – ideal for research, development, and industrial applications.

The CLASSIC Series also features state-of-the-art SWIR laser technology – ensuring reliable measurements even on dark, rough, or moving surfaces. With a focus on single-point and fiber-optic systems, the CLASSIC Series delivers maximum precision without the use of moving scanning units. Its intuitive operation and digital signal processing enable efficient execution of even complex measurement tasks.

Available in various models – from compact single-point to fiber-optic systems – the CLASSIC Series offers the right solution for every measurement environment.

The right vibrometer for every measurement task

Different types of vibrometers are used depending on the application – for single-point, surface, or three-dimensional vibration measurements.

Single-Point Laser Vibrometers

Single-point vibrometers enable high-resolution measurements at a single point on the test object – ideal for research, development, and quality control. Using Laser Doppler technology, even the smallest vibrations are detected with high accuracy and without physical contact.

Scanning Laser Vibrometers

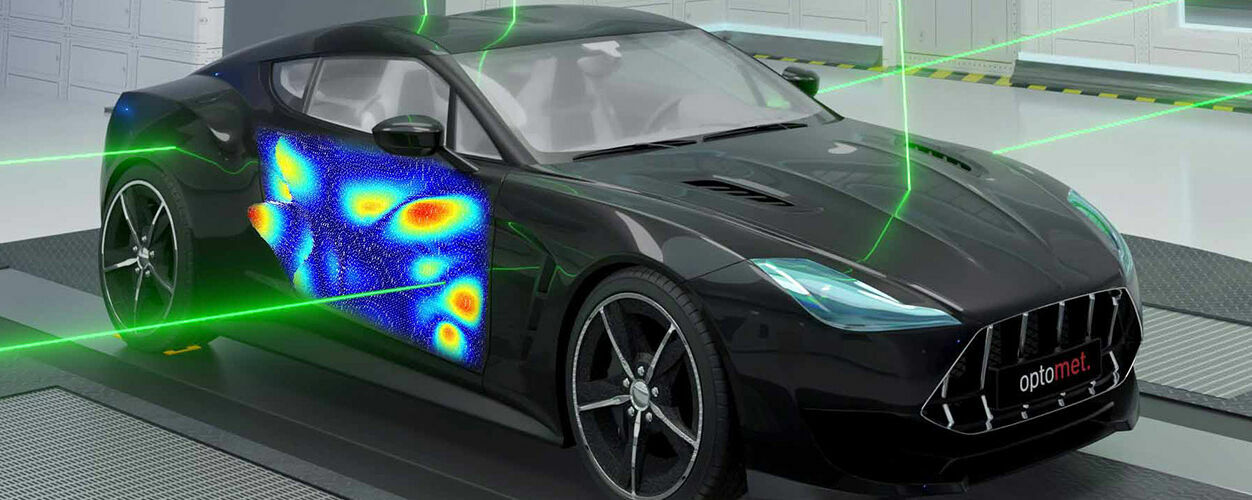

Scanning laser vibrometers automatically and non-contactly measure vibrations across a large number of points. This allows mode shapes, resonances, and vibrations over entire surfaces to be reliably visualized – ideal for modal analysis and structural dynamics investigations.

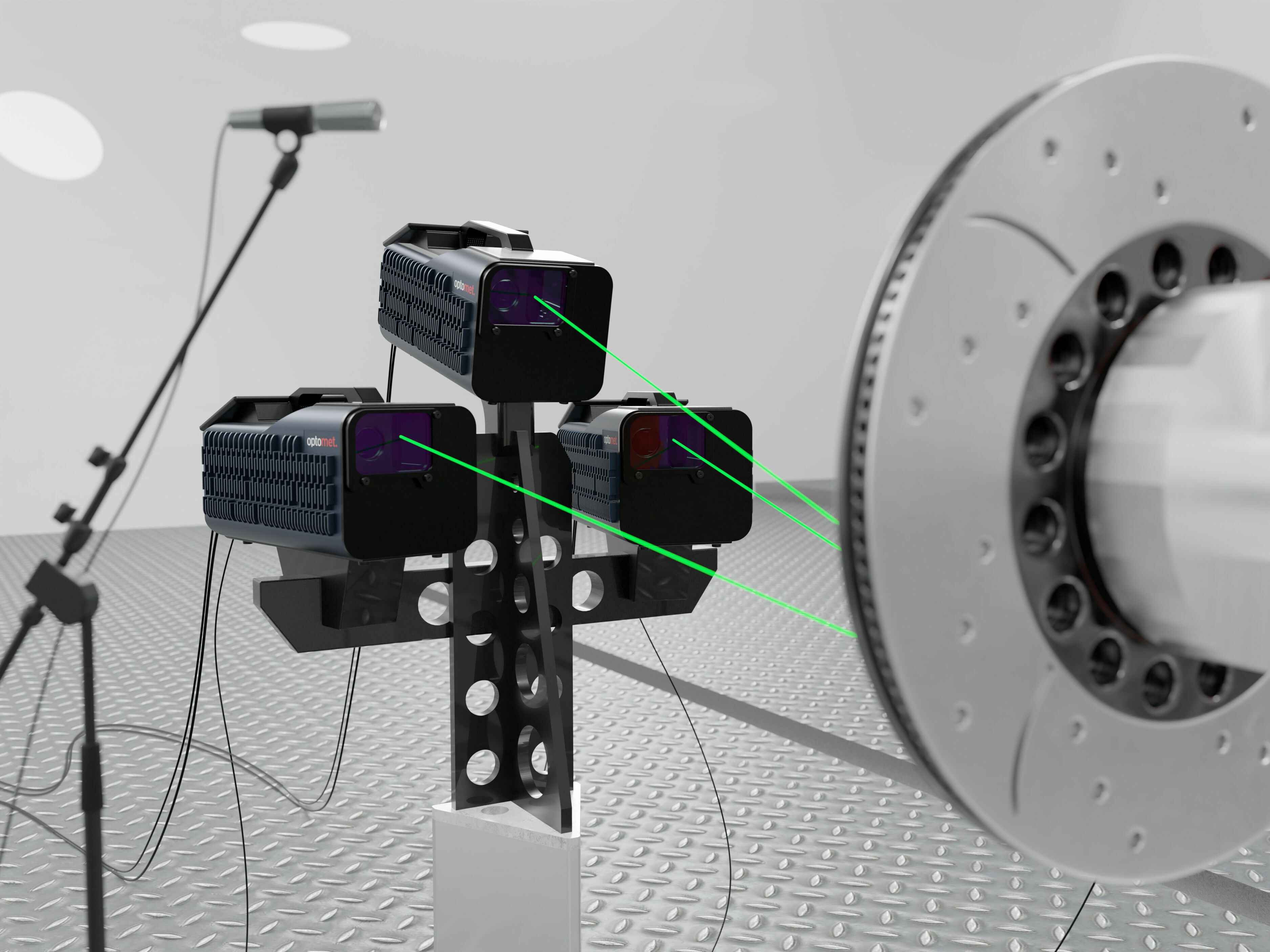

3D Laser Vibrometers

3D laser vibrometers measure vibrations simultaneously in three spatial directions (x, y, z) – both in-plane and out-of-plane. This technology provides a complete motion profile and is ideal for applications requiring the analysis of directional dependencies or complex structures.

Laser sources for different applications

Besides the geometry of the measurement system, the choice of laser source is crucial. Depending on the application, Optomet employs HeNe lasers for visible light or SWIR lasers for infrared measurements.

SWIR Laser Vibrometers

SWIR-based laser vibrometers operate at a wavelength of 1550 nm. This technology is the Optomet standard, representing high signal quality, long-term stability, and precision – ideal for demanding applications in research and industry.

Helium-Neon (HeNe) Laser Vibrometers

Laser vibrometers based on HeNe lasers are measurement systems with a visible laser source. They are particularly suitable for applications requiring measurements through media such as water, as well as for classical laboratory and industrial use where high sensitivity and easy handling are essential.

Related Terms & Knowledge

Laser Sources

Fundamentals of the laser types used in vibrometry – Helium-Neon, SWIR, and fiber-coupled systems.

Laser Doppler Vibrometry

Structure, operating principle, and application areas of Laser Doppler Vibrometry.

Vibration Measurement

Methods, measurement setup, and evaluation of vibration data in research and industry.

Doppler Effect

Physical principle of Laser Doppler Vibrometry – the basis for precise velocity measurement.

Signal Processing

Analysis of vibration data using FFT, frequency-domain evaluation, and real-time processing.

Downloads

Brochure SMART-Series (pdf)

Laser Vibrometry is getting SMART

One system, unlimited possibilities

Vibration measurement for research, development, and industry – Optomet provides the right solution for every application.

SMART Scan+

SMART Scan+

SMART 3D-Scan

SMART 3D-Scan

SMART Full Body

SMART Full Body

SMART Single+

SMART Single+

SMART Multi-Fiber

SMART Multi-Fiber

SMART 3D-Fiber

SMART 3D-Fiber

SMART DAQ

SMART DAQ

Software SMART Lab

Software SMART Lab

Scanning Vibrometer

Scanning Vibrometer

Vector-Series

Vector-Series

Vector-Micro-Optics

Vector-Micro-Optics

Nova-Series

Nova-Series

Nova-Xtra

Nova-Xtra

Fiber-Series

Fiber-Series

Fiber-Multiplex

Fiber-Multiplex

Fiber Micro Manipulator

Fiber Micro Manipulator

OptoSCAN

OptoSCAN

OptoGUI

OptoGUI

Single-Point Vibrometers

Single-Point Vibrometers

Scanning Vibrometers

Scanning Vibrometers

3D-Laser Vibrometers

3D-Laser Vibrometers

Acoustics & Ultrasonics

Acoustics & Ultrasonics

Aerospace and aviation

Aerospace and aviation

Automotive

Automotive

Biology & Medicine

Biology & Medicine

Brake noise

Brake noise

Civil Engineering

Civil Engineering

Electronics & Household Devices

Electronics & Household Devices

Materials Research

Materials Research

Medical technology

Medical technology

Tools & Machinery

Tools & Machinery

Turbine

Turbine

Wind tunnel testing

Wind tunnel testing