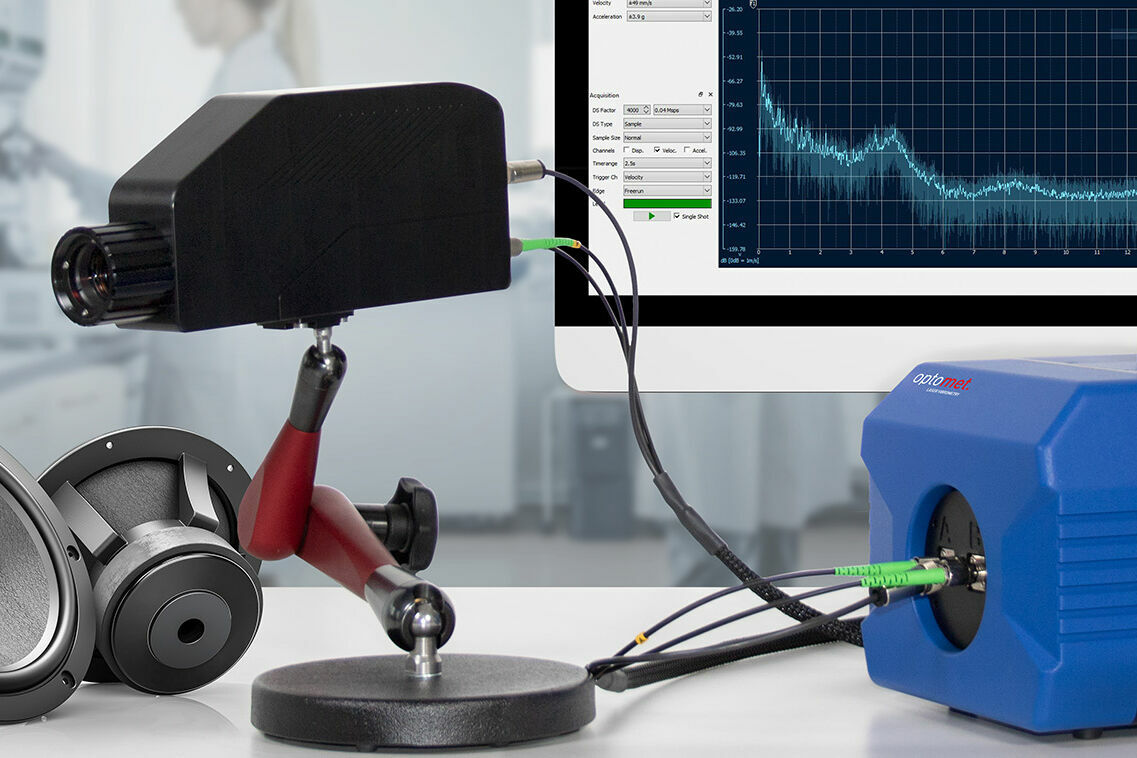

During a single-point measurement, the laser beam is directed onto a defined position on the surface. The Doppler shift of the reflected light caused by the motion is evaluated in the integrated interferometer to precisely determine the object’s velocity, displacement, and acceleration – completely non-contact and without influencing the object.

Single-point measurement process

Typical measurement workflow: from setup to analysis

Step 1: Preparation and connection

The vibrometer is powered on and then connected. The connection can be established via Ethernet to a PC. In this case, the device is detected by its IP address in the Optomet software. Alternatively, the measurement signals can be fed directly into your own data acquisition system via the analog output.

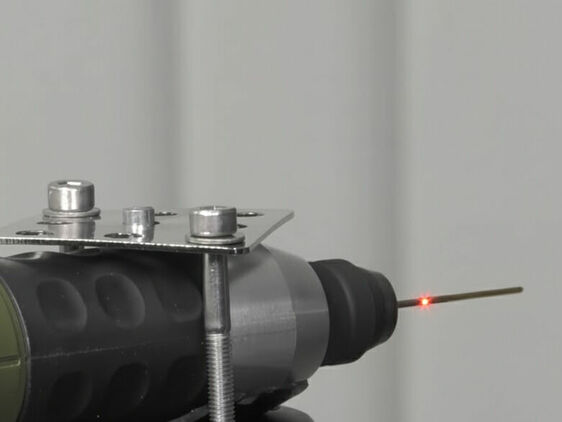

Step 2: Alignment and focusing

The green pilot laser indicates the measurement spot. After alignment, the system automatically focuses to the defined working distance. This ensures a stable backscattered signal.

Step 3: Measurement and analysis

After checking the signal, the measurement range and filters are selected. The vibration signals are acquired with up to 312 MSamples/s across a frequency range from DC to 50 MHz. Velocity, displacement, and acceleration are visualized in real time.

Ready to measure in about 5 minutes

After powering on and automatic focusing, the system is ready for use within just a few minutes – from connection to the first measurement.

- Live measurement and display of velocity, displacement, and acceleration

- Time and frequency domain analysis

- Automatic peak finder for displaying maximum amplitudes

- Recording and export of measurement data

- DC–50 MHz frequency range

- Suitable for rotating and moving objects

- Measure vibrations up to 50 m/s

- Best displacement resolution: 0.05 pm

- Variable working distances between 0.006 m and 300 m

1D single-point, 3D single-point, and multi-point compared

Depending on the measurement task, single-point vibrometers capture vibrations in one direction, in three directions, or at multiple positions simultaneously.

The choice of variant depends on the objective of the measurement: whether a single vibration needs to be analyzed precisely, the motion in three spatial directions must be determined, or the behavior of several points is to be examined at the same time.

1D single-point measurements

1D vibrometers capture vibrations along a single spatial axis, i.e., in the direction of the laser beam.

This variant is ideal for targeted single-point measurements – for example, for characterizing individual components, performing modal analyses, or conducting quality inspections in production environments.

Since the measurement is completely non-contact, the test object remains unaffected – even for sensitive or very fast-moving structures.

Typical applications include the structural analysis of buildings and bridges, the inspection of rotating tools or drives such as drills and bearings, quality assurance in production lines, and the vibro-acoustic analysis of loudspeakers, sensors, or microphone components.

3D single-point measurements

3D vibrometers combine three laser beams in a single system and measure the motion of the measurement point in all spatial directions (x, y, z).

This enables the determination of complete vibration vectors and the precise analysis of complex motion patterns.

Typical applications are found in research and development, for example in measurements on hot or difficult-to-access components in engine test environments, where conventional triaxial accelerometers cannot be used due to contact mounting requirements or high temperatures.

3D vibrometers enable fully contactless measurements, offering all the advantages of optical methods in such environments.

Multi-point measurements

Multi-point measurements can be implemented in different ways:

In the SMART series, synchronization is fully integrated: several SMART single-point vibrometers communicate directly with each other and synchronize digitally via Ethernet. If required, the time base can also be GPS-supported, enabling precise alignment of measurements even across different locations.

In addition, multi-fiber systems are available. These include the SMART Multi-Fiber as well as the Fiber series in the CLASSIC product line. Both allow multiple fiber-coupled sensor heads to be connected to a single device and are particularly well suited for applications where several measurement points need to be captured in parallel.

This enables precise analysis of complex motion behavior, for example in industrial quality control or research.

"For more than two decades, Optomet has stood for precise vibration measurement. Our single-point laser vibrometers provide reliable data – from laboratory analysis to industrial quality control."

Tobias Schröder (M.Sc. Mechanical Engineering)

Head of Sales & Marketing

Comparison: Single-point and scanning vibrometers

|  | |

|---|---|---|

| Measurement principle | Measures vibration at a defined point along the laser axis. | Automatically scans a surface and measures at many points to create a complete vibration map. |

| Repositioning | Required when a different point needs to be measured. Alternatively possible by using multiple single-point vibrometers or fiber sensor heads. | Not required – the laser beam is deflected via an integrated mirror and automatically guided across the measurement area. |

| Spatial information | 1D information (velocity, displacement, acceleration along one axis) | 2D or 3D surface information, depending on the system configuration |

| Typical applications | Single-point measurements on machines, tools, bridges, or components in quality inspection | Full-field vibration analysis, modal analysis, and structural investigation of complex components |

Single-point vibrometers from Optomet at a glance

Optomet offers single-point laser vibrometers in two product lines, each addressing different requirements.

Laser vibrometers of the CLASSIC series stand for robust systems with a clear structure and straightforward configuration – ideal for established measurement tasks in laboratories and industrial environments. The SMART series expands this approach with fully integrated system communication: multiple devices can be directly connected, precisely synchronized, and flexibly combined into modular measurement setups. In addition, data acquisition is already integrated into the system and operates in real time.

Nova (Classic series)

The CLASSIC Nova series is a digital free-beam laser Doppler vibrometer (LDV) with a SWIR laser source (1550 nm).

It combines high signal stability with a robust design and is particularly well suited for measurements on dark, rough, or hot surfaces.

Learn more about the Nova series | Nova series datasheet (PDF)

_7c6e5406cc.jpg)

Nova-Xtra (Classic series)

The CLASSIC Nova-Xtra extends the Nova series with a system designed for long-distance measurements of up to 300 m.

This free-beam SWIR laser vibrometer is intended for applications where vibrations must be measured on distant or hard-to-access structures – such as in civil engineering, aerospace, or large-scale facility inspections.

SMART Single+

The SMART Single+ combines vibrometer, data acquisition, and signal generation in a single device, following the “lab in a device” principle of the SMART series. All essential measurement, reference, and analysis functions are integrated, including the ability to connect additional sensors and visualize signals directly.

The system is modular and expandable: additional SMART devices can be directly linked and automatically synchronize with a shared time base. This enables flexible multi-point setups with consistent measurement data, suitable for efficient use both in laboratories and industrial environments.

Learn more about the SMART Single+ | Datasheet SMART Single+ (PDF)

SMART Multi-Fiber

The SMART Multi-Fiber enables simultaneous, synchronized vibration measurements at up to four points using a single device. With fiber-optic sensor heads, even hard-to-access areas can be reliably captured.

The system combines modular flexibility with precise data acquisition and is fully integrated into the SMART series.

Learn more about the SMART Multi-Fiber | Datasheet SMART Multi-Fiber (PDF)

Fiber (Classic series)

The CLASSIC Fiber series is based on the technology of the Nova series and extends it with compact, fiber-coupled sensor heads for maximum flexibility. The systems enable precise, sequential single-point measurements across multiple fiber heads.

Various fiber heads can be connected as an option, each optimized for different measurement distances and surface characteristics.

Learn more about the Fiber series | Datasheet Fiber series (PDF)

SMART 3D-Fiber

The SMART 3D-Fiber combines fiber-coupled measurement technology with three-dimensional vibration analysis. Three laser beams capture the motion of a single measurement point simultaneously in all spatial directions – ideal for applications where directional dependencies or complex deformation patterns need to be examined.

The system uses the modular architecture of the SMART series and can be flexibly synchronized with additional devices.

Learn more about the SMART 3D-Fiber | Datasheet SMART 3D-Fiber (PDF)

The key difference between the SMART Multi-Fiber and the multi-fiber solution of the CLASSIC series lies in the method of data acquisition. With the SMART Multi-Fiber, multiple measurement points are captured simultaneously, as all channels operate on a shared, automatically synchronized time base. In the CLASSIC Fiber series, data acquisition is performed sequentially; the measurement points are switched one after another, typically with a switching time of around 20 ms.

Versatile applications in research and industry

Single-point laser vibrometers are used in a wide range of applications to measure vibrations precisely and without contact — from product development to end-of-line testing.

They enable measurements on diverse structures and materials and provide reliable data for research, development, and quality assurance.

Typical applications:

- End-of-line test stands in production and quality assurance

- Automated measurement tasks with digital or analog interface integration

- Long-distance measurements on bridges, buildings, or industrial structures (e.g., up to 300 m with Nova Xtra)

- Vibration analysis on machine components for detecting resonances and imbalances

- Structural investigations on thin-walled components, sheets, or plates

- Microstructural analysis on MEMS components (Micro-Electro-Mechanical Systems)

- Acoustic investigations on loudspeaker membranes, microphones, and sensors

FAQ: Single-point laser vibrometers

Here you will find answers to frequently asked questions about the function, application, and integration of single-point laser vibrometers.

A single-point laser vibrometer measures vibration velocity, displacement, or acceleration at a single defined point. In contrast, scanning or 3D vibrometers capture vibrations across multiple points or simultaneously in several spatial directions.

Single-point systems are ideal when a specific measurement point needs to be examined in detail — for example, for resonance analysis, material testing, or functional verification of individual components.

Laser vibrometers | SMART Scan+ | SMART 3D-Scan | SMART 3D-Fiber

A single-point vibrometer is used when individual structures or components need to be examined with high precision. This is especially relevant in quality assurance, research, or test bench environments where targeted point measurements are required.

Typical applications include vibration analysis of machine components, materials, medical devices, civil structures, or MEMS components.

The vibrometer directs a laser beam onto the surface of the test object. From the frequency shift of the reflected light caused by the vibration (Doppler effect), the system calculates the motion of the measurement point.

This method is completely non-contact and requires no physical attachment of sensors to the object.

Because the system measures without physical contact, it does not affect the mass of the test object. This results in unaltered, accurate measurement data — even for sensitive, hot, or moving components.

In addition, there is no installation effort as with conventional sensors, and measurements can be performed quickly and with high repeatability.

Yes. Through manual or automated positioning, the vibrometer can measure sequentially at different points. In combination with multiple devices or fiber-coupled sensor heads (e.g., SMART Multi-Fiber), multiple points can also be captured simultaneously.

This allows the system to be flexibly adapted to the specific measurement task.

Single-point vibrometers offer digital and analog interfaces such as Ethernet, USB, or BNC, allowing them to be directly integrated into test benches, measurement systems, or automated production processes.

Trigger inputs and outputs make it possible to seamlessly integrate the systems into existing test benches and automation workflows.

In principle, measurements can be taken on almost any surface — including dark, rough, or shiny materials. The SWIR laser technology (1550 nm) used in Optomet systems ensures stable signal quality, even on challenging surfaces.

The possible measurement distance depends on the system type. Standard devices of the SMART and CLASSIC series cover distances from a few millimeters to several meters.

Specialized models such as the CLASSIC Nova-Xtra enable measurements over distances of up to 300 m — for example, for structural testing or outdoor inspections.

The CLASSIC series offers robust, clearly structured systems designed for established measurement tasks in laboratory and industrial environments. Data acquisition is digital but intended for single-device operation or sequential multi-point measurements — in multi-fiber configurations, the measurement points are switched one after another.

The SMART series expands this concept with a fully integrated system architecture. Multiple devices can be directly linked and automatically synchronized, enabling multi-point measurements to be captured simultaneously. Setups can be flexibly extended and combined into modular measurement systems, including a shared time base and integrated analysis functions.

Both series are based on the same optical measurement principles but differ in system architecture, expandability, and the way multi-point measurements are implemented.

Optomet systems are operated using SMART Lab (SMART series) or OptoGUI (CLASSIC series). Both applications provide remote control, data acquisition, and real-time analysis of measurement data.

The data can be further processed via open interfaces (e.g., MATLAB, LabVIEW, or Python) or integrated into existing systems.

Related Terms & Knowledge

Laser Sources

Fundamentals of the laser types used in vibrometry – Helium-Neon, SWIR, and fiber-coupled systems.

Laser Doppler Vibrometry

Structure, operating principle, and application areas of Laser Doppler Vibrometry.

Vibration Measurement

Methods, measurement setup, and evaluation of vibration data in research and industry.

Doppler Effect

Physical principle of Laser Doppler Vibrometry – the basis for precise velocity measurement.

Signal Processing

Analysis of vibration data using FFT, frequency-domain evaluation, and real-time processing.

Downloads

Brochure SMART-Series (pdf)

Laser Vibrometry is getting SMART

One system, unlimited possibilities

Vibration measurement in research, development, and industry — Optomet offers the right solution for your application.

SMART Scan+

SMART Scan+

SMART 3D-Scan

SMART 3D-Scan

SMART Full Body

SMART Full Body

SMART Single+

SMART Single+

SMART Multi-Fiber

SMART Multi-Fiber

SMART 3D-Fiber

SMART 3D-Fiber

SMART DAQ

SMART DAQ

Software SMART Lab

Software SMART Lab

Scanning Vibrometer

Scanning Vibrometer

Vector-Series

Vector-Series

Vector-Micro-Optics

Vector-Micro-Optics

Nova-Series

Nova-Series

Nova-Xtra

Nova-Xtra

Fiber-Series

Fiber-Series

Fiber-Multiplex

Fiber-Multiplex

Fiber Micro Manipulator

Fiber Micro Manipulator

OptoSCAN

OptoSCAN

OptoGUI

OptoGUI

Single-Point Vibrometers

Single-Point Vibrometers

Scanning Vibrometers

Scanning Vibrometers

3D-Laser Vibrometers

3D-Laser Vibrometers

Acoustics & Ultrasonics

Acoustics & Ultrasonics

Aerospace and aviation

Aerospace and aviation

Automotive

Automotive

Biology & Medicine

Biology & Medicine

Brake noise

Brake noise

Civil Engineering

Civil Engineering

Electronics & Household Devices

Electronics & Household Devices

Materials Research

Materials Research

Medical technology

Medical technology

Tools & Machinery

Tools & Machinery

Turbine

Turbine

Wind tunnel testing

Wind tunnel testing